Modern industries rely heavily on complex electrical systems, and central to these systems are wire harnesses. Harnesses streamline multiple electrical pathways, ensuring they function seamlessly. An integral part of these wire harnesses is the specific junction types they incorporate, namely the Y, T, and X junctions. Let’s unravel the world of these junctions and their significance in industrial applications.

Wire Harnesses

A wire harness, commonly referred to as a cable assembly, is a collection of electrical wires or cables responsible for conveying electrical power or signals. Bound by cable ties, straps, or protective conduits, these harnesses ensure organization, safeguard the cables from potential harm, and minimize the chances of electrical interference or short-circuiting.

Real Industrial Applications

Wire harnesses find their applications in virtually every industry that relies on electricity:

- Automotive: Cars, trucks, and other vehicles use harnesses to connect their myriad electrical components, from lights to the ignition system.

- Aerospace: Aircraft require highly organized and secure electrical systems, making wire harnesses crucial.

- Home Appliances: Everything from your washing machine to the refrigerator employs a wire harness to function correctly.

Why Different Junctions?

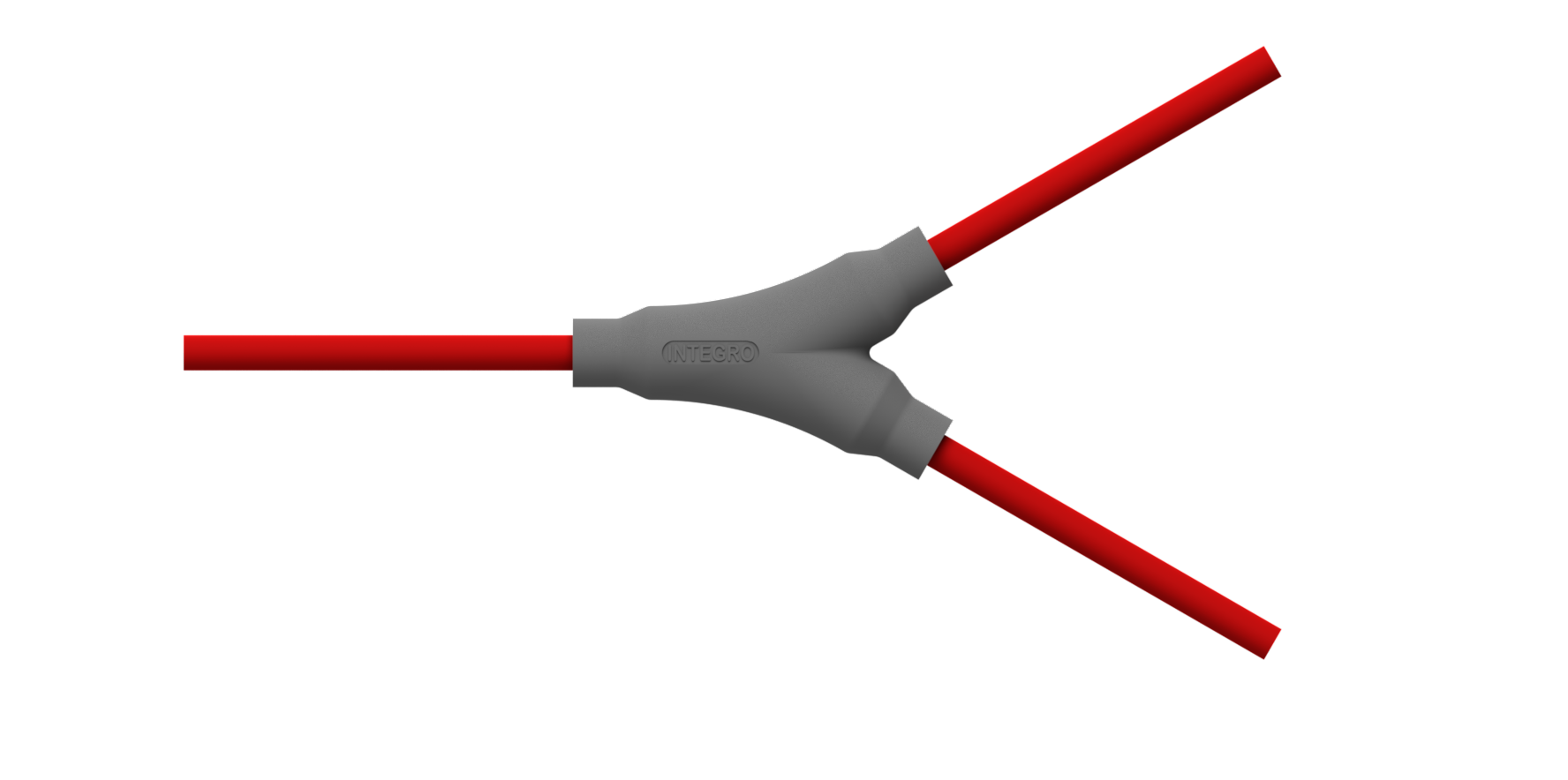

Different electrical setups demand different branching patterns, and this is where our Y, T, and X junctions come into play. Each serves a unique purpose:

- Y Junction: Consider the use in home theater systems. You might need to split the main audio feed into two: one for the speakers and another for the subwoofer. A Y junction will take the primary feed and bifurcate it, ensuring both the speaker and subwoofer receive the audio input.

- T Junction: Let’s take the example of an industrial assembly line. The main power source may need to be split so that it can simultaneously power the conveyor belt motor and the lighting above the belt. A T junction is perfect for such applications, splitting the primary route into two distinct pathways at a 90-degree angle.

- X Junction: Imagine a large office setup with centralized control for both lighting and air conditioning. The main electrical feed might need a four-way split: one for each quadrant of the office. An X junction ensures that the electrical feed is divided evenly, powering each quadrant’s lights and AC units.

Concluding Thoughts

The complexity of modern electrical systems necessitates specific tools and components to ensure they operate without a hitch. Y, T, and X junctions, in conjunction with wire harnesses, play a pivotal role in maintaining the order, efficiency, and safety of these systems. By understanding the nuances of each junction type, industries can ensure optimal performance, longevity, and safety in their electrical applications.