Wires and cables are essential components of any electrical system, providing the necessary pathways for electricity to power devices, machinery, and infrastructure. However, like any other electrical component, wires and cables are susceptible to various issues that can disrupt functionality and safety. In this article, we will explore common types of wires and cables, such as copper and tray cables, and discuss the typical problems that can occur, their causes, how to diagnose them, and potential solutions.

Types of Wires and Cables

Before diving into the problems, it’s essential to understand some common types of wires and cables used in various applications:

Copper Cables

Copper cables are widely used in electrical systems due to their excellent conductivity and durability. They are commonly used in residential, commercial, and industrial wiring for power distribution, telecommunications, and electronics.

Tray Cables

Tray cables are specifically designed for installation in cable trays, raceways, and other exposed applications in industrial environments. These cables are often used in power distribution, control, and signal transmission systems, and they are known for their robustness and resistance to environmental factors.

Common Problems with Wires and Cables

Despite the durability and reliability of copper and tray cables, they are not immune to issues. Here are some common problems that can occur:

Fraying

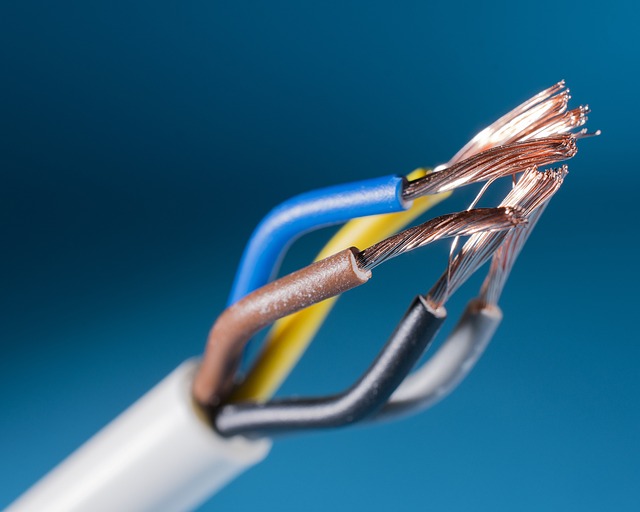

Fraying occurs when the outer insulation or jacket of a wire or cable becomes worn, exposing the internal conductors. This can lead to safety hazards, including electrical shock, short circuits, and fire.

Causes

- Aging: Over time, the insulation material can degrade due to exposure to environmental factors such as UV radiation, moisture, and temperature fluctuations.

- Mechanical Stress: Repeated bending, twisting, or abrasion can cause the insulation to wear down.

- Poor Installation: Incorrect installation, such as over-tightening cable ties or sharp bends, can damage the insulation.

Diagnosis

To diagnose fraying, visually inspect the cables for signs of wear and tear, such as exposed conductors, cracks in the insulation, or discoloration. In more severe cases, use a multimeter to check for continuity and insulation resistance.

Solutions

- Replacement: The most effective solution for frayed wires is to replace them entirely. Continuing to use frayed wires can lead to further damage and safety risks.

- Protection: To prevent fraying, use protective coverings such as cable sleeves or conduits and ensure proper installation techniques.

Short Circuiting

A short circuit occurs when there is an unintended connection between two points in an electrical circuit, allowing current to flow along an unintended path. This can result in overheating, equipment damage, and even fire.

Causes

- Damaged Insulation: Worn or frayed insulation can cause conductors to touch, leading to a short circuit.

- Moisture Ingress: Water or moisture entering the cable can cause the conductors to short.

- Faulty Connections: Loose or improperly connected wires can cause a short circuit.

Diagnosis

Short circuits can be diagnosed using a multimeter to check for continuity between the conductors. Additionally, look for signs such as tripped circuit breakers, blown fuses, or scorched areas around the wiring.

Solutions

- Repair or Replace: If the short circuit is caused by damaged insulation, the affected section of the wire should be repaired with electrical tape or replaced entirely.

- Drying and Sealing: In cases where moisture is the culprit, dry the cables thoroughly and seal any entry points to prevent future moisture ingress.

- Proper Connections: Ensure all connections are tight and secure to prevent short circuits.

Overheating

Overheating occurs when a wire or cable carries more current than it is rated for, causing the insulation to melt and potentially leading to fires.

Causes

- Overloading: Connecting too many devices to a single circuit can cause the wires to overheat.

- Improper Sizing: Using wires with an inadequate gauge for the current load can lead to overheating.

- Poor Ventilation: Lack of airflow around cables, especially in tightly packed environments, can contribute to overheating.

Diagnosis

Signs of overheating include discolored or melted insulation, a burning smell, and hot spots along the length of the wire. Use an infrared thermometer to check the temperature of the wires.

Solutions

- Load Balancing: Distribute the electrical load across multiple circuits to prevent overloading.

- Correct Sizing: Ensure that the wires used are of the appropriate gauge for the current they are carrying.

- Improve Ventilation: Ensure adequate airflow around cables and avoid bundling them too tightly.

Conclusion

Wires and cables are critical to the safe and efficient operation of electrical systems, but they can be prone to problems such as fraying, short circuiting, and overheating. Understanding the causes of these issues and knowing how to diagnose and address them is essential for maintaining the safety and reliability of your electrical installations. Whether you’re dealing with copper cables in a residential setting or tray cables in an industrial environment, taking proactive steps to prevent and fix these common problems can save time, money, and potentially lives. Always prioritize regular inspections and maintenance to ensure the longevity and safety of your wiring systems.