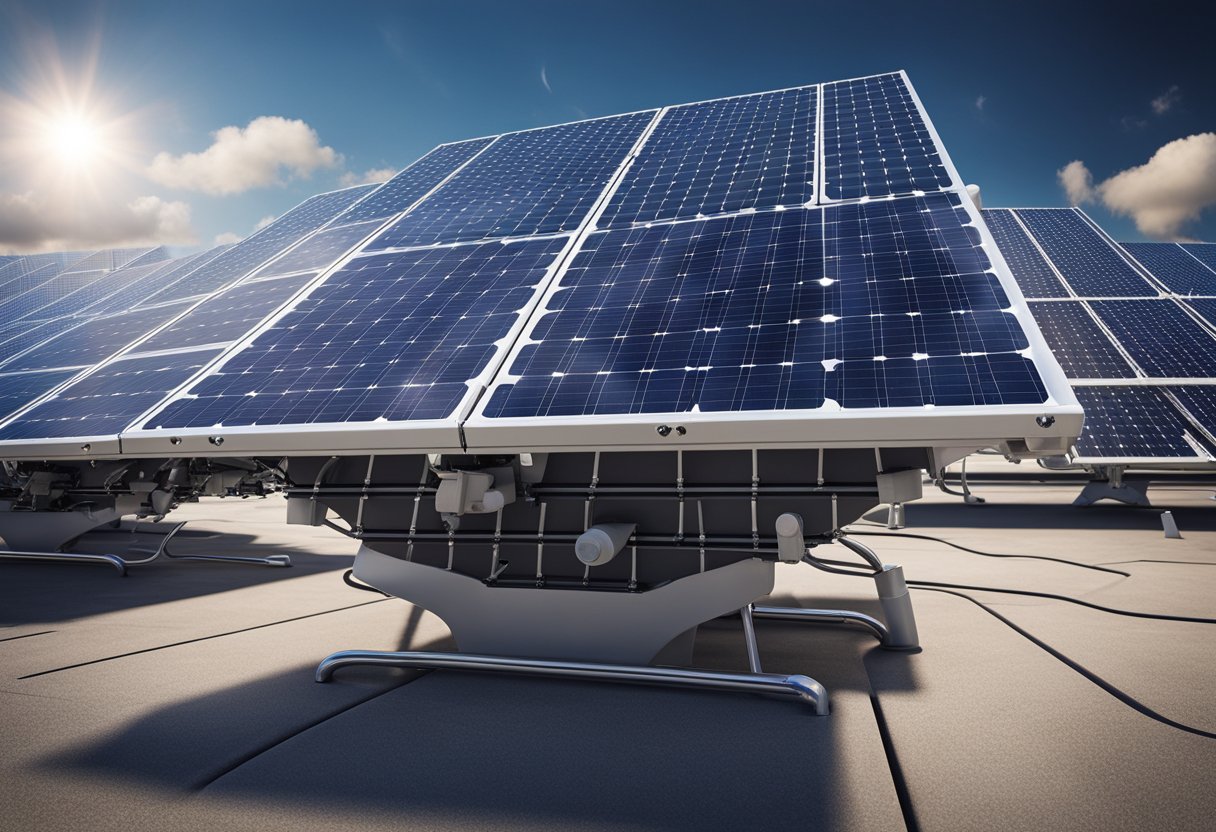

As we continue our journey toward a more sustainable future, solar energy stands at the forefront of the renewable revolution. A critical element in harnessing this clean power is the evolution of solar wire standards, which ensure maximal efficiency and safety. The ability of solar wires and cables to adapt to advancements in solar technology and meet rigorous safety standards is paramount for the growth and reliability of solar power systems.

We’ve seen significant developments in the specifications of solar wires, tailored to handle varying voltage ratings and withstand harsh environmental conditions. This advancement is crucial as it directly impacts the efficiency of solar panels and the overall performance of solar energy systems. By focusing on future-proof designs, our industry is paving the way for seamless integration of solar power into diverse applications.

Understanding the ongoing changes in solar wire standards enables us to build more resilient solar energy solutions.

Key Developments in Solar Wire Standards

Recent advancements in solar wire standards focus on enhancing compliance with regulations, improving material technology, and ensuring compatibility with environmental considerations. These changes aim to increase the reliability, efficiency, and safety of solar energy systems.

National Electrical Code (NEC) Requirements

The National Electrical Code (NEC) outlines essential guidelines ensuring the safety and performance of electrical installations, including photovoltaic systems. Key updates in recent versions target increasing safety by detailing requirements for adequate conductor sizing and grounding methods. For example, Article 690 specifies regulations for PV systems. Compliance with NEC is critical to protect against risks like overheating by offering clear directives on wire use, installation practices, and connection standards.

Major Types of Solar Wires and Cables

Solar installations use various types of wires catering to distinct functions. PV wire is widely used due to its superior UV resistance and ability to withstand harsh temperatures. THHN, THW, and THWN are other common types utilized in conduit systems for their durability. These wires come with insulation that can handle direct sunlight and environmental stress. Choosing the right type depends on the specific needs of the solar project, including voltage requirements and environmental exposure.

Advances in Insulation and Conductor Materials

Innovations in wire insulation and conductor materi als lead to enhanced performance and reliability. New insulation materials, such as cross-linked polyethylene (XLPE), provide better UV resistance and durability under temperature extremes. Meanwhile, improved conductor materials, like tinned copper, reduce corrosion and enhance conductivity. These developments are crucial in preventing energy loss and ensuring consistent performance of solar installations, particularly in challenging environments.

als lead to enhanced performance and reliability. New insulation materials, such as cross-linked polyethylene (XLPE), provide better UV resistance and durability under temperature extremes. Meanwhile, improved conductor materials, like tinned copper, reduce corrosion and enhance conductivity. These developments are crucial in preventing energy loss and ensuring consistent performance of solar installations, particularly in challenging environments.

Impact of Environmental and Safety Standards

Environmental and safety standards significantly influence solar wire design and usage. For instance, wires exposed to environmental conditions like direct sunlight and temperature variations need enhanced UV and weather resistance. These standards ensure that wires can withstand temperature extremes and resist wear. ASTM standards emphasize the need for fire safety compliance, pushing manufacturers to create products that limit fire risks while maintaining efficiency and durability. Adaptations in response to these standards are crucial for maintaining safety and performance in solar systems.

Impacts on Solar Photovoltaic Systems and Installations

Evolving standards in solar wiring profoundly influence how solar photovoltaic systems are designed, installed, and maintained. We delve into the aspects of wire selection, system performance, installation practices, and future trends impacting solar technology.

Choosing the Right Wire for Solar Applications

Selecting the correct wire for solar applications is crucial to system efficiency and safety. Wires come in various types, such as DC solar cables and AC cables. It’s important to consider the wire gauge, which directly affects voltage drop and power output.

If the gauge is too small, the resistance causes power loss, decreasing the system’s effectiveness. This selection impacts how we connect solar panels, whether in series or parallel, influencing overall system performance and cost-effectiveness.

Performance, Durability, and Maintenance Considerations

Performance and durability in solar installations depend heavily on the quality of the wiring. The wires must withstand environmental hazards like UV exposure and harsh weather. Rigid conduits offer protection, enhancing system structural integrity.

Proper maintenance reduces risks of electrical shorts and extends the life of photovoltaic systems. Regular checks ensure there are no loose connections or wear and tear, which could impede functionality. Sustainable practices in maintaining wires are vital for long-term power output.

Installation Practices and System Integration

Installation quality is paramount for seamless integration of solar panel arrays. Techniques in connecting solar panels, ensuring quality electrical wiring, and proper alignment with charge controllers and inverters are critical.

Attention to detail during wiring can prevent costly power loss and ensure smoother power transitions between DC and AC systems. Installation practices must also focus on minimizing installation time while maintaining system integrity, enabling efficient setups even in large-scale solar farms.

Trends Shaping Future Solar Wire Standards

Future solar wire standards are influenced by innovations in materials and design improvements. As system designs become more efficient, there is a push to use fewer cables per megawatt installed. This not only cuts costs but also reduces waste.

Rigid conduit use and advances in cable technology promise longer-lasting, more reliable systems.