When you’re working on electrical projects, knowing the actual wire gauge—insulation included—is a pretty big deal for safety and making sure everything fits as it should. To measure wire gauge with insulation, you want to figure out the total outside diameter of both the wire and its insulating layer, not just the metal inside. This way, you’ll end up with the right connectors, terminals, or conduits, and hopefully avoid any headaches later.

You might notice a lot of wires look nearly identical, but the real size can actually change quite a bit depending on insulation thickness. Getting an accurate measurement of the full diameter saves you from confusion and some potentially expensive mistakes when you’re matching up components or laying out an installation. So, how do you get a good measurement? Here’s a breakdown of the process, so you can get it right and feel pretty confident about your wiring job.

Understanding Wire Gauge and Insulation

Wire gauge is what tells you about a wire’s electrical capacity, but insulation type and construction are what actually determine how it behaves when you use it. If you want to measure wire gauge with insulation, it’s worth understanding the difference between solid and stranded wire—and how insulation plays into things.

What Is Wire Gauge?

Wire gauge is basically the thickness or diameter of an electrical wire. In the US, we usually go by the American Wire Gauge (AWG) system, and here’s the thing: a smaller AWG number actually means the wire is thicker.

Take 12 AWG copper wire, for example—it’s beefier and can handle more current than 18 AWG. The gauge affects not just how much current you can send through, but also things like voltage drop, so picking the right size really does matter.

You’ll see lower AWG (thicker) wires in high-power setups, and higher AWG (thinner) wires where you don’t need as much juice. Always check your voltage, amperage, and what you’re actually doing before picking a wire—there’s no one-size-fits-all.

Types of Wire Insulation

Insulation wraps around the conductor to stop short circuits, keep moisture out, and make the wire tougher. The usual suspects for insulation are PVC, Teflon (PTFE), and rubber.

Each material has its own quirks—like temperature ratings, flexibility, or how well it stands up to chemicals. PVC is everywhere for general use, while Teflon is the go-to for high heat or nasty environments.

Insulation thickness does change the overall wire diameter, so you’ve got to strip it or at least account for it when measuring. Manufacturers usually list both the conductor and full diameter (with insulation) in their tables, so it helps to double-check those specs.

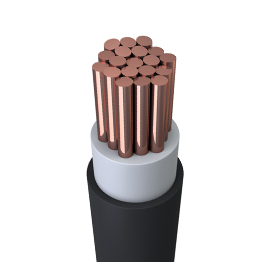

Solid vs. Stranded Wire

Solid wire is just what it sounds like—a single chunk of conductor. It’s a bit better for conductivity and is often used in places that don’t need to bend, like inside walls.

Stranded wire, on the other hand, is made up of a bunch of thinner wires twisted together. That makes it way more flexible, which is handy for cables that need to move around or deal with vibration.

Both types use the same AWG system, but stranded wire can look a little thicker because of the air gaps between strands and how insulation wraps around it. So when you’re measuring, keep in mind if you’re dealing with solid or stranded wire—it can change how you strip and measure it.

How to Measure Wire Gauge with Insulation

Measuring wire gauge with insulation isn’t rocket science, but you do need to know what you’re looking for and how to use the right tools. You’ll want to be precise, read your measurements carefully, and remember that insulation thickness can throw off your numbers if you’re not careful.

Required Tools and Preparation

For measuring wire gauge with insulation, here’s what you’ll need:

- Digital calipers—these give you a precise outer diameter (OD) reading.

- Wire strippers or cutters—useful if you want to get at the bare wire.

- An AWG wire gauge chart (printed or on your phone) to compare measurements.

- Paper and pen—old-school, but handy for jotting stuff down.

Make sure your calipers are zeroed out and the jaws are clean. Straighten out the wire so it’s not all bent up. If you know what kind of insulation you’re dealing with, having the manufacturer’s specs for thickness is a bonus.

Step-by-Step Measurement Process

- Straighten the wire and lay it flat.

- Place the caliper jaws around the outer insulation, closing them gently so you don’t squish the insulation too much.

- Check the outer diameter (OD) on your calipers—write it down in millimeters or inches.

If you want to be more precise, you can strip off a bit of insulation and measure the bare conductor. But if that’s not possible, you’ll need to estimate the insulation thickness when you look at your results.

It’s not a bad idea to take a few measurements along the wire, especially if you suspect the insulation isn’t perfectly uniform.

Interpreting AWG Tables for Insulated Wire

AWG tables are based on the bare conductor diameter, not the full insulated size. For example, a 14 AWG solid copper wire is usually about 1.63 mm (0.0641 inches) across without insulation. If you’re measuring OD with the insulation on, it’ll be bigger.

Here’s how you can get to the right gauge:

- Estimate insulation thickness (check the manufacturer’s info—let’s say it’s 0.5 mm per side).

- Subtract twice the insulation thickness from your OD to get the bare wire diameter.

- Compare that number to an AWG table to find the closest match.

For bigger wires, you might run into circular mils or MCM (thousand circular mils) instead of AWG, especially in industrial settings. Those tables work the same way—just match up your measurements to the chart.

Factors Affecting Measurement Accuracy

A bunch of things can throw off how accurately you measure wire gauge:

- Insulation thickness isn’t really standardized—different manufacturers and wire types do their own thing, so your guess might be off if you don’t have the exact specs.

- Deformation from caliper pressure can squish the insulation a bit, which usually means you’ll underestimate the diameter.

- If the wire’s stranded instead of solid, the actual conductor area ends up a bit less than a solid wire with the same outside diameter. Kind of surprising, but true.

Ambient temperature can mess with the size of both the wire and the insulation. And if you’re trying to figure out things like current-carrying capacity, resistance, or voltage drop, you’ll definitely want to check the manufacturer’s data. These specs just depend so much on the actual conductor size and whatever insulation they used. Honestly, if you want to be sure, grabbing the technical datasheet is always your safest bet.