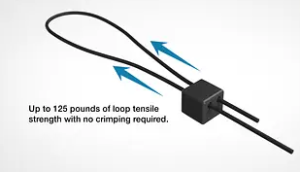

Cable management in solar installations has traditionally required tools, time, and significant manual effort that can strain installers throughout long workdays. The Heyco Crimpless Sunbundler eliminates the need for crimping tools while providing the durability of stainless steel construction with smooth vinyl jacketing that protects cable insulation.

We’ve seen how conventional cable ties often fail in outdoor environments, but this innovative solution combines the strength of commercial aircraft-grade stainless steel with a user-friendly cube design. The releasable and reusable feature allows installers to adjust positioning during installation without waste.

Understanding how this tool-free cable management system works and where it excels can help solar professionals streamline their installations while maintaining the high standards required for long-term outdoor performance. We’ll explore the technical specifications and practical applications that make this cable tie system stand out in demanding solar environments.

Overview of Heyco Crimpless Sunbundler

The Heyco Crimpless Sunbundler represents a tool-free cable management solution featuring PVC-coated stainless steel construction designed for solar installations. This system eliminates traditional crimping requirements while providing reusable functionality for cable positioning and maintenance needs.

Key Features and Specifications

The Crimpless Sunbundler utilizes PVC-coated stainless steel wire construction that delivers durability in outdoor environments. We find this coating provides UV protection essential for solar applications. The cable ties feature a crimpless cube design that enables installation without specialized tools. This design reduces physical strain on installers during repetitive tasks.

Key specifications include:

- Maximum tensile strength ratings for secure bundling

- Variable bundle diameter capacity

- Stainless steel core with PVC coating

- DFARS compliance for certain applications

The ties maintain releasable and reusable functionality. We can reposition cables during initial installation or access them later for repairs and replacements.

Multiple size options accommodate different bundle diameters. The product line includes various models like the SunBundler 20 and SunBundler 44 for specific applications.

How the Crimpless System Works

The installation process requires no crimping tools or specialized equipment. We simply loop the loose end around the cable bundle and insert it into the designated hole. Parts arrive with one end pre-terminated and ready for immediate use. The installer pulls the loose end tight to secure the bundle in position. The cube design incorporates a locking mechanism that maintains tension without requiring external crimping force. This system holds cables securely while allowing for future adjustments.

Removal options include:

- Cutting one side and pulling the wire through

- Using the Heyco removal tool (Part Number S6390)

- Releasing both sides for complete reuse

The crimpless system maintains consistent performance across multiple installation and removal cycles.

Benefits of Using Heyco Crimpless Sunbundler

Installation efficiency improves significantly without tool requirements. We eliminate the need to carry crimping tools to job sites, reducing equipment costs and setup time. The design reduces repetitive strain on installers who handle multiple cable ties daily. This ergonomic advantage becomes substantial during large solar array installations.

Economic benefits emerge from the reusable design. We can reposition cables during installation without discarding ties, and maintenance teams can access cables without permanent damage to management systems. The stainless steel construction provides long-term durability in harsh outdoor conditions. Solar installations benefit from corrosion resistance and mechanical strength over extended periods.

Flexibility in cable management allows for future modifications. We can adjust cable routing or add new circuits without replacing the entire management system.

Applications and Installation

The Heyco Crimpless Sunbundler serves multiple roles in solar and electrical installations through its tool-free design and durable construction. These cable ties eliminate repetitive strain injuries while providing secure bundling for indoor, outdoor, and underground applications.

Typical Use Cases in Solar and Electrical Systems

We commonly deploy Crimpless Sunbundlers in photovoltaic installations where quick cable management is essential. The releasable design allows us to reconfigure solar panel connections without cutting ties.

Electrical panel applications benefit from the crimpless mechanism. We can bundle control wires and power cables without carrying crimping tools to confined spaces.

The ties work effectively for underground and direct burial installations. Their UL certification under Specification 62275 ensures compliance with electrical codes for buried applications.

Outdoor electrical systems represent another key use case. We rely on these ties for weatherproof cable management in exposed installations where traditional zip ties might fail.

Installation Guidelines and Best Practices

No tools required for basic installation sets these ties apart from crimped versions. We simply wrap the cable bundle and secure the mechanism by hand. For optimal bundle tension, we recommend grouping cables of similar diameter together. This prevents smaller wires from loosening over time.

Temperature considerations matter during installation. We avoid installing in extreme cold where materials become brittle, following standard electrical installation practices. The reusable feature allows us to adjust installations during commissioning. We can release and retighten the same tie multiple times without degradation.

Proper routing requires maintaining minimum bend radii for enclosed cables. We ensure the tie placement doesn’t create stress points on conductor insulation.

Compatibility with Cables and Connectors

Solar cable compatibility includes standard MC4 connector assemblies and DC feeder cables. The ties accommodate typical 10-14 AWG solar conductors commonly found in residential installations.

AC wiring applications work with THWN and USE-2 cable types. We successfully bundle multiple 12 AWG branch circuits using single ties.

Connector clearance requirements vary by manufacturer. We maintain adequate spacing around junction boxes and combiner enclosures to prevent interference with covers.

Cable jacket materials including XLPE, PVC, and rubber compounds work with the vinyl-clad stainless steel construction. The smooth interior surface prevents jacket damage during installation.