In the ever-evolving electrical industry, certain components play pivotal roles in maintaining safety and enhancing system efficiency. One such indispensable tool is the Wiley Bonding Jumper. As a staple in electrical grounding applications, Wiley Bonding Jumpers provide a reliable and robust path for electrical continuity and conductivity.

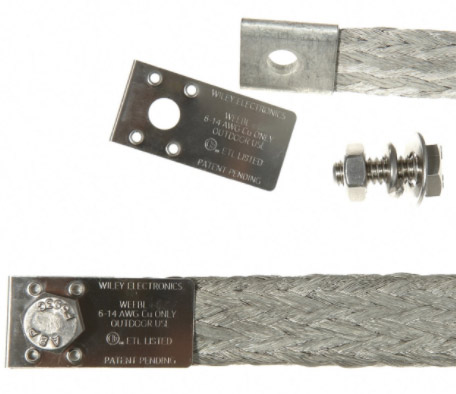

Broadly speaking, a Wiley Bonding Jumper is a braided wire designed to form a bridge between two metallic surfaces, ensuring they have the same electrical potential. This is vital in reducing the risk of electrical shock and minimizing potential damage from voltage transients. When it comes to grounding and bonding, these jumpers truly are unsung heroes.

Choosing the Right Length

Choosing the correct length for a Wiley Braided Bonding Jumper is a critical step. The length of the jumper is contingent upon the specific requirements of the electrical system and the distance between the two points being bonded. Essentially, the jumper should be long enough to span this distance without causing undue tension that could lead to damage or disconnection.

However, a jumper that’s overly lengthy can present its own challenges, potentially creating obstacles or snags, and taking up valuable space within an installation. Therefore, exact measurements of the area and careful consideration of the spatial conditions are crucial in determining the appropriate length of a Wiley Bonding Jumper.

The Pivotal Role of Wiley Bonding Jumpers in Business Applications

Wiley Bonding Jumpers prove their mettle across a wide range of commercial and industrial applications. In sectors where electrical systems and equipment form the lifeblood of operations, these components are vital. For instance, data centers, heavily reliant on grounding to ensure smooth, uninterrupted operations, utilize Wiley Bonding Jumpers to provide stable connections.

Manufacturing facilities, particularly those dealing with sensitive electronic components, benefit from the electrostatic discharge prevention offered by effective bonding. Here, these jumpers help maintain a consistent electrical potential across different surfaces. Energy providers, particularly solar energy installations, also use these bonding jumpers extensively to ensure system safety and efficiency.

Final Thoughts: The Unseen Power of Wiley Bonding Jumpers

In closing, Wiley Bonding Jumpers may not always be in the spotlight, yet their role is pivotal. They ensure the safety and functionality of numerous electrical systems, spanning diverse industries. By selecting the appropriate jumper length and understanding its application, businesses can leverage these seemingly insignificant components to drive safety measures and augment system performance. Wiley Bonding Jumpers truly embody the axiom that great things come in small packages, reinforcing the importance of every piece in the intricate puzzle of electrical system design.