Solar installations really put cable management to the test—decades of blazing sun, freezing winters, and constant weather shifts can chew up traditional plastic zip ties in just a few years. If you’ve ever spent time maintaining a solar array, you know those brittle ties turn into a mess pretty fast, risking both safety and reliability. It’s a hassle nobody wants to deal with.

CableLoc cable ties are something else entirely—think stainless steel core, a tough polymer jacket, and a design that skips the need for tools. These heavy-duty ties handle up to 120 pounds of loop load, and the UV-stabilized coating shrugs off corrosion and weather like it’s nothing.

So, what makes CableLoc worth considering? Let’s look at the design, where they actually shine in real-world solar installs, and how to pick the right specs for your next project. If you’re aiming for long-term reliability and less maintenance, it’s definitely worth knowing what sets these cable ties apart.

Overview of CableLoc Cable Ties

CableLoc cable ties are built around a stainless steel core with a polymer coating—made with solar and electrical work in mind. They’re tool-free, and honestly, they last way longer than those old plastic ties.

Key Features and Benefits

Tool-Free Operation

No more digging around for tools. CableLoc’s fastening mechanism is patent-pending and just works. You can secure cables fast, and it’s pretty straightforward.

Enhanced Durability

That stainless steel core is the real deal. It’s much stronger than plastic, supporting up to 120 pounds of loop load. Not bad, right?

Weather Resistance

The UV-stabilized vinyl coating isn’t just for show—it actually keeps the tie from breaking down outdoors. The polymer jacket helps these ties go the distance.

Slack Storage Feature

There’s a built-in system for slack, which allows for cable expansion and contraction. It’s a small touch, but it matters when temperatures swing.

Extended Warranty

A 25-year warranty? That’s a bold move. It definitely shows they trust their product to stick around.

Types and Configurations

Standard Length Options

Mostly, CableLoc sticks with a 14-inch cable tie. The CL1514-1 model is their bread and butter.

Load Specifications

These ties are no slouch—they’ll handle loop loads up to 120 pounds. The 7×7 stranded construction keeps the strength consistent.

Application-Specific Design

It’s clear these were made with solar in mind. The design fits the quirks of photovoltaic cable management.

Materials Used in Manufacturing

Stainless Steel Core

The 7×7 stranded 300-series stainless steel core is tough, resisting corrosion and holding up under harsh conditions.

Polymer Coating System

A UV-stabilized vinyl coating wraps the steel. That jacket isn’t just for looks—it keeps cables safe from abrasion and stays flexible.

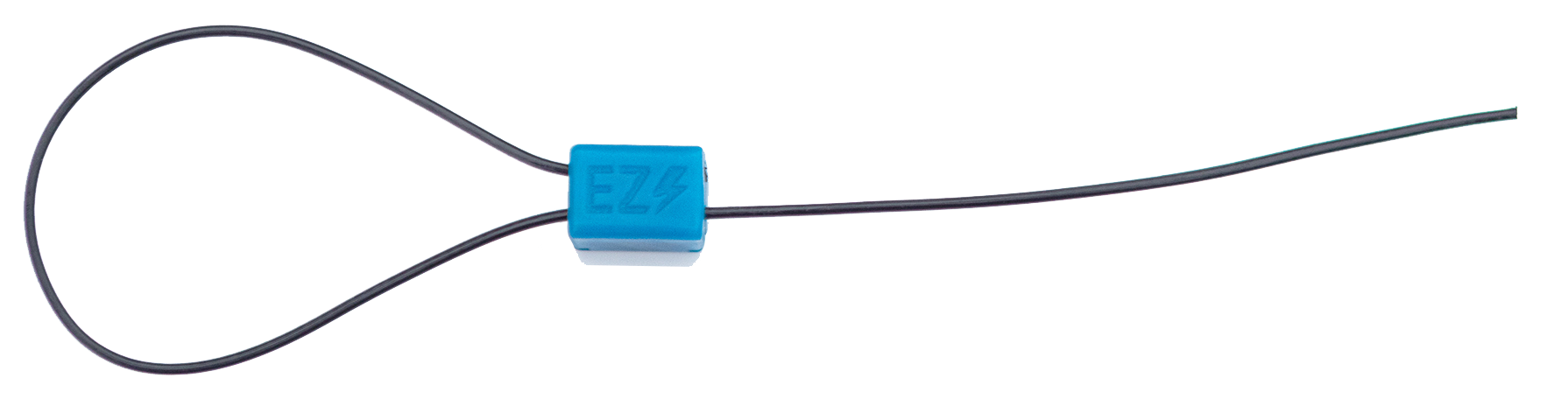

Lock Body Construction

The lock body is rugged polymer, and you don’t need tools. It stands up to temperature swings and sun exposure without falling apart.

Certification Standards

CableLoc checks the boxes for UL 62275 Type 21S, plus UL 2239 and CSA C22.2#18.4. So, the compliance side is covered.

Applications of CableLoc Cable Ties

Some environments just chew up plastic ties, but CableLoc stands up to the challenge. Whether it’s industrial construction or electrical installs in the field, these stainless steel ties bring durability you can count on.

Industrial and Construction Uses

In rough industrial settings, CableLoc cable ties hold their own. That stainless steel core doesn’t corrode and keeps its strength even when conditions get ugly. On construction sites, the 120-pound loop load capacity comes in handy. You can bundle heavy cables or secure equipment without reaching for extra tools.

Industrial uses often include:

- Equipment mounting in factories

- Structural cable management in big storage spaces

- Outdoor installs where weather is unpredictable

- Heavy machinery wire organization

The polymer jacket is gentle on wires, so you’re not slicing into insulation like with some old-school ties. Temperature swings? Not really a problem here. These ties hold up from -40°F to 185°F, so unless you’re working on Mars, you’re probably covered.

Electrical and Solar Installations

Honestly, solar panel installs are where CableLoc really shines. These ties are designed for photovoltaic wire management, and it shows. The UV-stabilized vinyl coating keeps them from crumbling under the sun. That 25-year warranty is a big comfort for anyone worried about long-term performance.

Key electrical uses:

- DC wiring between panels

- Inverter cable bundling and routing

- Grounding wire management

- Conduit attachment points

Tool-free installation saves time, especially on rooftops. The fastening system is quick and lets you make adjustments without cutting and tossing ties. Getting cable spacing right is easier, too. The slack storage feature makes room for expansion and contraction, so you’re not left with loose wires after a hot day.

Selecting the Right CableLoc Cable Tie

CableLoc cable ties have that stainless steel core and polymer jacket, but you’ll want to think about load, environment, and size before picking one. It’s not a one-size-fits-all deal.

Load Ratings and Strength Options

Because of the stainless steel core, CableLoc ties have way better tensile strength than plastic. They stay strong across temperature swings where plastic would just snap or stretch. It’s smart to check the total weight of your cable bundles, plus any extra movement or vibration. These ties don’t lose their grip over time like plastic ones do. Different diameters mean different strengths. Thicker cores can take on heavier bundles and more tension. You’ll want to match the tie to your actual cable loads and stresses.

Environmental Considerations

That polymer jacket? It’s not just for corrosion resistance—it also cushions the cables. This combo works well outside, in chemical-heavy places, or when temps swing wildly (see here).

UV light destroys plastic ties fast. CableLoc’s jacket holds up under the sun for years. Salt and moisture can’t get to the steel core, either. Plastic ties get brittle and crack with temperature changes, but the steel core here stays flexible and strong from -40°F up to 185°F. It’s worth considering how much your cables and mounting surfaces expand and contract when you’re choosing lengths.

Size and Length Selection

Bundle diameter really sets the baseline for how long your tie needs to be—if it’s too short, well, things just won’t close up right. Usually, we check the thickest part of the cable cluster to make sure there’s enough material to wrap around everything comfortably.

CableLoc ties are pretty flexible with bundle sizes, thanks to their adjustable setup. Any extra length? It just tucks away in the built-in slack storage, so you don’t have to bother cutting or tossing scraps. That’s honestly a relief—no more dealing with those sharp little bits from regular ties.

We try to think ahead about possible cable additions when picking out lengths. Since these ties are reusable, you can tweak or rearrange things later without grabbing a new one every time. You’ll find standard lengths for everything from tight, tidy setups to those big industrial trays where you need a lot more reach.