Introduction

PV connectors are critical components of any solar project since they are the conduits via which DC solar electricity is delivered from PV modules to inverters via cables.

- Connectors must provide low-resistance connections that decrease resistive losses when energy passes through the array in order for a system to provide AC power safely and dependably.

- Withstand environmental exposure for more than 25 years with negligible corrosion, deterioration, or current leakage.

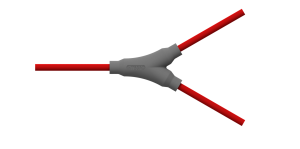

However, there is no industry-wide standard for PV connector design. These electromechanical devices normally have a male component, which is an internal plug that encloses a conta

ct, and a female portion, which is a socket with an extended contact. An electrical circuit is formed by tightly locking these two pieces together. The most important indicator of latent failure is hot connectors, or connectors with high operating temperatures. Because field-made connectors cannot

be internally inspected after installation without destroying them, any other danger indicators are usually hidden from view.

Connectors and Fires

In several worldwide solar markets, connectors are a leading source of fires caused by PV systems. These sporadic occurrences endanger people’s lives, property, and even the public perception of solar power. There have been reported occurrences of PV system fires and connector failures, albeit many are confidential:

- In the UK, 27% of fires involving a PV system was caused by the connectors from 2010 to 2017.

- In Germany, connectors were the main cause of 24% of PV system fires from 1995-2012.

- SunPower initiated a huge $30MM USD replacement program due to cracking and fire concerns in third party supplied products.

There were around 375 million PV connections in the United States as of December 2021, and an estimated 3.5 billion PV connections worldwide. Each of these unique connectors is a potential point of failure, yet only a small percentage of them are checked on a regular basis. Fires in running assets caused by faulty connectors can be avoided, but only if the proper inspection and testing processes are used.

Signs of Failure

The obvious signs of failure are: loose or disconnected connectors; high temperatures; melted, discolored or cracked casings; arc faults and ground faults; fires. But these field observations are only the symptoms of deeper challenges:

- Uneven, insufficient or improper surface contact on metal contacts.

- High resistance due to soiling, corrosion or foreign particles.

- Moisture or water ingress that creates alternate electrically conductive paths, typically resulting from a broken seal and/or separated connectors.

- Material degradation due to environmental factors.

When fundamental errors are made during connector production, procurement, or installation, or when a natural disaster or force majeure event occurs, the situations stated above occur.

What Causes Failure in PV Connectors

- Improper Installation

- Improper Installation Tools

- Lack of training for installers

- Mismatched connectors

- Counterfeit Connectors

- Faulty Material

Best Ways to Reduce Failures

- Specify Connectors – Specify certified connectors by manufacturer and exact product type in both module supply agreements and EPC contracts. Mandate and validate product authenticity to avoid counterfeits.

- Install the right connectors – Do not allow cross-mated connectors unless they are tested and certified together as a single component. Obtain new connectors from module manufacturers if necessary.

- Install connectors properly – Use manufacturer-provided crimping tools. String modules immediately to prevent environmental exposure and use end caps when necessary. Document the status and location of all field-made connectors at the time of installation.

- Validate Connector Installations – Include third-party as-built inspection and verification requirements in EPC contracts. Ensure connectors are covered under EPC warranties.

- Regularly Inspect Connectors – Periodically inspect connectors throughout the project lifecycle using Solar Grade software and an acceptable quality level (AQL) sampling approach. Always conduct inspections after force majeure events because they can compromise the integrity of well-made connectors.

- Purchase Pre-Made Wire and Connector Assemblies – Monroe has the ability to custom build all your PV assemblies to order and to your exact specifications. This removes the guess work and ensures you are getting the correct wire and connectors to reduce the risk of failure and fire. Speak to your sales rep today if you could benefit from the time savings and extra piece of mind of having your PV assemblies pre-built by an industry leader like Monroe Titan.

** Source – PVEL & HelioVolta Ultimate Safety Guide for Solar PV Connectors